I'm curious, what am I missing?

your missing that this rear suspension was designed to be SCCA legal.

then would there be other ways of modifying the frame/suspension to make it even better without going all the way to C4? (probably a dumb question, but I can't think of why quite yet - so be gentle)

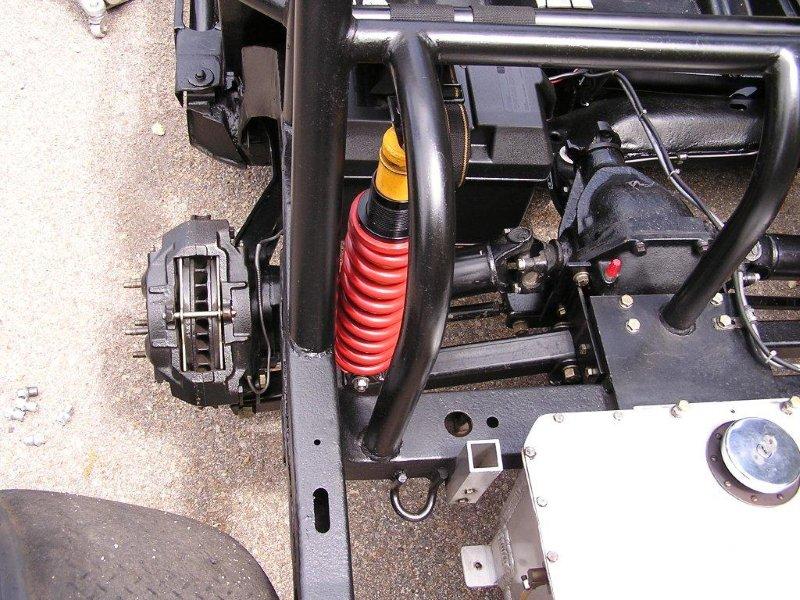

The toe control is what they where after. Three different designs are in the pictures. Which one are you referring to? The Ryding, Rilley/Guldstrand and the Greenwood. Extensively raced in Gt1 when the SCCA allowed suspension mounting points to be relocated. Was used until the tube frame C4 killed the GM C3 framed racer. Look at picture 15 for the Ryding design. The Ryding mounts to the stock trailing arm location on the frame. You got to remember the roll cage attachment points and lots of frame bracing are done to these cars. These cars are far from stock. Greenwood, Rilley and Guldstrand built some of the most advanced chassis during that period. Ryding was a Engineer at GM and from what I understand, designed the C4 rear end.

I'm only asking about the links that run parallel to the frame - what is the advantage of having 4 points rather than 3? As a tangential question, to use a 5 link (4 points instead of 3, and presuming a roll bar), would you need to run a brace from the upper link attachment at the frame and triangulate to the frame at some point near the middle of the door?