SuperBuickGuy

Well-known member

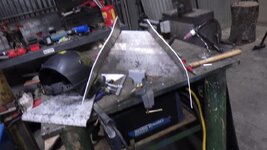

time for a test fit

someone mentioned I don't know how to weld aluminum.... this wasn't me, it was magick

then weld in the stand

then install the hood

some say I don't learn - I say, see the hood and I'm checking clearance before I build the top piece? yeah, lurnin'

and it clears... woo and hoo!

time to cut out the top pieces

then time to temper the metal

soot

and then I question why I didn't pick up 5152 or 3003 aluminum on Friday...

I'm going to try to bend this around but I give it about a 30% chance

someone mentioned I don't know how to weld aluminum.... this wasn't me, it was magick

then weld in the stand

then install the hood

some say I don't learn - I say, see the hood and I'm checking clearance before I build the top piece? yeah, lurnin'

and it clears... woo and hoo!

time to cut out the top pieces

then time to temper the metal

soot

and then I question why I didn't pick up 5152 or 3003 aluminum on Friday...

I'm going to try to bend this around but I give it about a 30% chance