73 Mike

I'll drive it someday

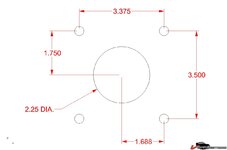

Does anyone have a picture of the adapter plate for a hydroboost unit for a manual brake conversion? I know that they are thicker than those used for power brake units and I presume it will have provisions for two bolts through the firewall rather than four. I also presume that the placement of the pushrod will be higher on the firewall since the hole for a manual brake is a little higher.

I've never been very happy with how my brake pedal ended up after converting to hydroboost. My car was a manual brake car that had already been converted to power, though not very well. In particular, even adjusted all the way in on the shortest pushrod, I think the brake pedal is too high.

Dimensions for the different plates would be extremely helpful as well.

As always, thanks! :drink:

I've never been very happy with how my brake pedal ended up after converting to hydroboost. My car was a manual brake car that had already been converted to power, though not very well. In particular, even adjusted all the way in on the shortest pushrod, I think the brake pedal is too high.

Dimensions for the different plates would be extremely helpful as well.

As always, thanks! :drink: