Richard454

Well-known member

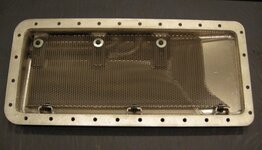

The rest of the Dry Sump system....

I'm running a Peterson 3 stage- uses a gerotor type pump. Made a bracket out of 1/2" aluminum - still working on the mandrel to hold the HTD drive on the Crank/harmonic balancer.

I took the factory bracket and had my buddy weld on a AN12 bung for the oil to the block. I'm making fittings for the factory oil canister-it has a pressure valve that will keep the oil from draining back to the pump/tank- so I don't have to worry about priming it. The stock BMW Oil canister has a bypass for too much pressure and is switched at temperature to send the hot oil to the factory oil cooler.....

I'm gonna run a Canton tank- about 7.5 qt capacity...add the oil cooler & large factory filter I'll have a couple more qts than the stock system.

Here's where it's gonna go-Mock up box-I'm losing the vacuum tank...but was thinking..running a dry sump system I'll have a lot of vacuum all the time- so really no need at all for the tank.

I've got all my AN fittings- next I'll have to start making the 7 hoses...

Getting closer to at least starting it....

Richard

I'm running a Peterson 3 stage- uses a gerotor type pump. Made a bracket out of 1/2" aluminum - still working on the mandrel to hold the HTD drive on the Crank/harmonic balancer.

I took the factory bracket and had my buddy weld on a AN12 bung for the oil to the block. I'm making fittings for the factory oil canister-it has a pressure valve that will keep the oil from draining back to the pump/tank- so I don't have to worry about priming it. The stock BMW Oil canister has a bypass for too much pressure and is switched at temperature to send the hot oil to the factory oil cooler.....

I'm gonna run a Canton tank- about 7.5 qt capacity...add the oil cooler & large factory filter I'll have a couple more qts than the stock system.

Here's where it's gonna go-Mock up box-I'm losing the vacuum tank...but was thinking..running a dry sump system I'll have a lot of vacuum all the time- so really no need at all for the tank.

I've got all my AN fittings- next I'll have to start making the 7 hoses...

Getting closer to at least starting it....

Richard

Last edited: