vette427sbc

Well-known member

What projector are you going to use for the headlights?

If you havent already bought those, take a look at www.theretrofitsource.com

I have a set of their Morimoto projectors in my vette (can share pics if you want some ideas on how to do yours). I deal with alot of the amazon projectors that customers bring in, and out of the box they are only OK.

One of the reviews said that once they were tweaked the light output was much better... I think theretrofitsource has some info on how to do this if you end up going this route

I already own them but there's a caveat - I never bought bulbs because these are basically to test the concept and fabricate the doors... when it's done, I'll put in something good (rather then cheap). the tl;dr is thank you, I will need that link in a bit for the 'real' lights.

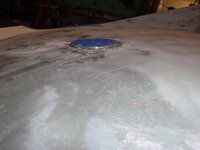

the question to be answered next is going to be whether or not I can weld new buckets on the doors... cast aluminum is not a happy metal to try and weld because it's usually full of crap. With that said, carbon fiber is an option....

I already own them but there's a caveat - I never bought bulbs because these are basically to test the concept and fabricate the doors... when it's done, I'll put in something good (rather then cheap). the tl;dr is thank you, I will need that link in a bit for the 'real' lights.

the question to be answered next is going to be whether or not I can weld new buckets on the doors... cast aluminum is not a happy metal to try and weld because it's usually full of crap. With that said, carbon fiber is an option....

Ahhhh OK :thumbs:

I had a local fabricator weld my headlamp supports (same crap potmetal) back together... he said the metal was trash to weld but it worked. If you are welding buckets to the headlamps for the projector, make some kind of isolator between the projector and the car. I noticed any movement or vibration is severely magnified by the projector on my car

What are you going to use to protect the lights from rocks when the lids are up?

that style just isn't mine... not anything wrong with it and it's a pretty sweet way of making lemonade out of a crappy situation.

the other bit is I plan on center lights - and driving mostly with those... not just that but it'd be pretty simple to add a row of LED lights in the grill openings - all while maintaining the stockish look..... dunno, I'll keep posting pictures as I narrow in on what I want....

i dont have one of those......is it a slip roller with cut outs for making rings? how do you control the diameter less tension?