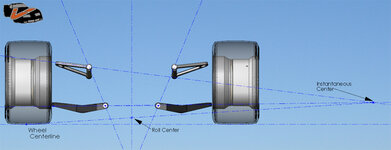

I was interested in dropped spindles for a C3 but couldn't find anything that was less than 2" drop, probably too much. Also found that these cause a number of issues and may no longer be available. I started a thread about this and came to the conclusion that raising the lower cross shaft might be more doable and avoid issues.

http://vettemod.com/forum/showthread.php?t=5620

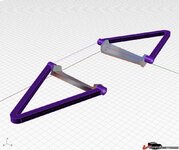

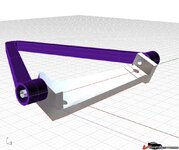

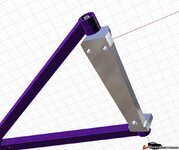

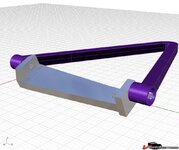

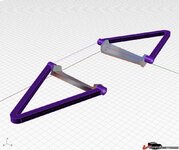

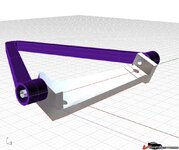

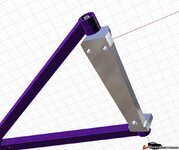

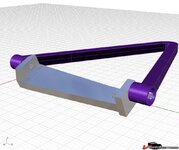

So I have done some CAD modeling to find out if this was an option and I think this will work. This is with the inner mount raised 1". Still need to add a brace between the fromt two mounts since the load is offset from the mount bolts.

http://vettemod.com/forum/showthread.php?t=5620

So I have done some CAD modeling to find out if this was an option and I think this will work. This is with the inner mount raised 1". Still need to add a brace between the fromt two mounts since the load is offset from the mount bolts.