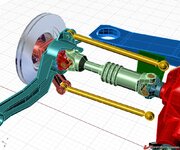

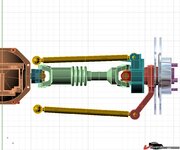

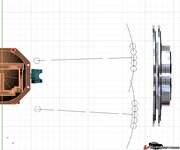

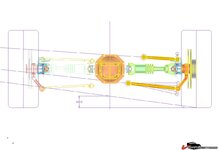

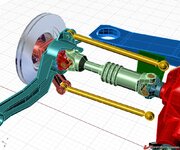

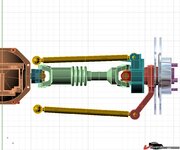

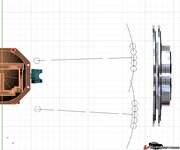

I am placing the inner mounts of the upper and lower links on my suspension. I have placed them so that I get .5 degree camber gain for every 1 inch of compression (at the struts). The circles in the line drawing (last picture) are 1 inch diameter. The rebound camber changes .4 degrees in the first inch and .1 in the next. So there is .5 degrees total in 2 inches of rebound.

Like to get some opinions before I make the brackets.

This is for a street driven car that might see some Auto-X but no track time.

Like to get some opinions before I make the brackets.

This is for a street driven car that might see some Auto-X but no track time.