bahamasair

Well-known member

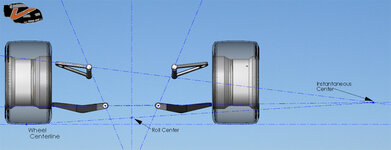

I'm trying to get the best angles possible for the tie rods on my rack install but have a couple of questions. Looking at this pic

you need to get the instant center to line up any of the other measurements but if I extend the lines along my a arms they will never meet

(thats not my car but is the same setup.)

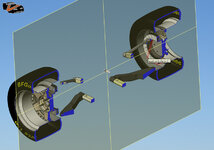

Looking at the first pic it shows instant center being behind the a arms but like my 2nd pic shows that will never happen. Should I be measuring from where the ball joints mount to the steering knuckle spindle like this?

Even if I do it wont make the instant center intersect behind the a arm. Should I assume instant center to be in front of the a arms like this?

Even if I do it wont make the instant center intersect behind the a arm. Should I assume instant center to be in front of the a arms like this?

Id like to get this as close as possible and since the body is off it will be easiest to measure it now.

I'm thinking I can get the instant center by extending my lines toward the wheel side of the a arms but would like to be sure and also want to be sure on where to measure at the steering knuckle.

Thanks for any help.

you need to get the instant center to line up any of the other measurements but if I extend the lines along my a arms they will never meet

(thats not my car but is the same setup.)

Looking at the first pic it shows instant center being behind the a arms but like my 2nd pic shows that will never happen. Should I be measuring from where the ball joints mount to the steering knuckle spindle like this?

Id like to get this as close as possible and since the body is off it will be easiest to measure it now.

I'm thinking I can get the instant center by extending my lines toward the wheel side of the a arms but would like to be sure and also want to be sure on where to measure at the steering knuckle.

Thanks for any help.

Last edited: