daveL82

Well-known member

- Joined

- Apr 10, 2008

- Messages

- 231

Well I haven't done much with the vette for several months as I've been doing a few track days on motorcycles and working on our place in Arkansas which is about 5 hrs from Dallas TX. The only time I can work on the property is every other weekend.

Today I pulled the coilovers, caliper, and managed to get the T-arm shims out of one side of the arm (doing one arm at a time). My sawzall is in AR so I'll have to retrieve that to cut the bolt and other shims out by the look of it.

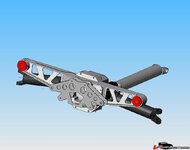

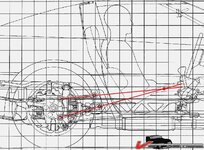

Plan is to use some of Marcks work along with some ideas from the Greenwood suspension. I previously fitted coil overs to the rear and added brackets to the strut rod bracket for a lower toe rod in parallel with the lower strut rod. Thought about an upper link lke the greenwood but wasn't sure I could locate the inner mounting point properly.

It'll be a slow project but it's a start.

Today I pulled the coilovers, caliper, and managed to get the T-arm shims out of one side of the arm (doing one arm at a time). My sawzall is in AR so I'll have to retrieve that to cut the bolt and other shims out by the look of it.

Plan is to use some of Marcks work along with some ideas from the Greenwood suspension. I previously fitted coil overs to the rear and added brackets to the strut rod bracket for a lower toe rod in parallel with the lower strut rod. Thought about an upper link lke the greenwood but wasn't sure I could locate the inner mounting point properly.

It'll be a slow project but it's a start.

Last edited: